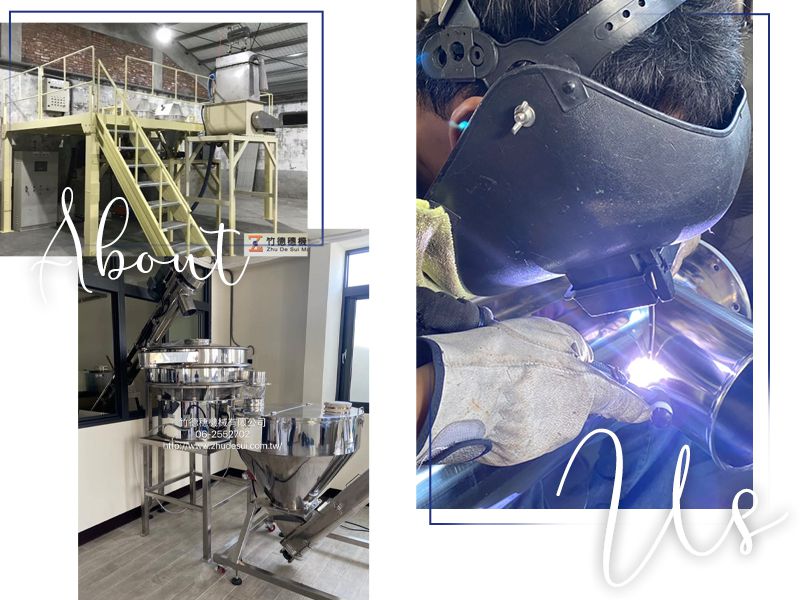

Zhu De Shi Co. Ltd (ZDS) is based in Tainan, Taiwan, found in year 2015, which is well established food processing machinery manufacturer and strive for advancing to a level to be an international oriented and competitive company.

Our personals offer such esteemed working experience, great energy level, enthusiasm, and technical innovations.

Speaking to the mission and service, nor only to be able to improve customer satisfaction and higher machinery quality, but also helping customers making profits with our respectable product commitment, versatile customization as advantage, as well as reducing chance of contamination by using high quality of stainless steel material, which meets GMP requirement, achieving both extended pharmaceutical and food quality level. By the end of 2020, we have successfully invented auto loading carton machine, as for the goal of 2021, we are planning to achieve ISO certificate. We are committed to well built reputation, never compromise on quality, and praised by customers and business industry.

One of the primary strengths is system customization, by knowing the material's characteristic, it enables us to make design total turnkey solution that could be semi-auto or full-auto according to customer preference, e.g., Integration as vibrating sifter, mill powder grinder, cutter, mixer/blender, conveyor, sugar pulverizier, packaging and carton machine.

Moreover, all equipments made by us are qualified and applied in industry plants e.g. food, biotechnology, chemical, pharmaceuticals, cosmetics, powder and granular quantitative and conveying equipment design and manufacturing and processing industries.

For the short and long term future plans, the company focuses on global marketing as its primary goal and sustainable company operation as its commitment. In addition, we will set up an international sales marketing department to explore more business opportunities, as well as to find foreign agent and distributor partners and will regularly participate in large well-known international food processing and packaging machinery exhibitions. Training is also a must to all staffs so they can gradually improve their knowledge and skills. Finally, it's already planned to establish a professional testing center to conduct material grinding, mixing, size grading tests for customers.

The enthusiasm is what have the most towards customer, we care customer proactively, understand that needs are, likewise, we sincerely take customer feedbacks as motivation moving forward to improve ourselves to be upscale level.

If there is any questions regarding to machineries, we sincerely welcome the inquiry and contact, that our customer service team are more than happy to serve you every needs.

Being an well experienced manufacturer for food stuff powder mixture and packaging solution. Our current worldwide customers include Taiwan, Indonesia, Vietnam, Japan, Nigeria, Australia and Northern Americas.

Offering completed solutions for all sizes of companies.

Capable of customizing and adjusting system designs, according to user request and preference.

The primary advantage is having design and mechanical engineers who have had thirty-years experience in food stuff machinery business.

We do not produce a bunch of machines in stock, Instead, each individual one is built with handmade crafts, that makes it sturdy and durability, applied on different type of raw materials and food stuff.

To meet customer requests, we ensure that the machine meets our quality standards, including initial raw material checks, choosing steel materials to be processed, parts to be ordered and assembled, TIG welding or others to be required, drawings chart approval, assembly procedure and testing, and final check (such as RPM, balancing appearance and vibration) before delivery.

This is our quality commitment to our valued customers.

In addition to on sight survey, including false search, maintenance for mechanical and electrical malfunction, we also offer services for machinery recondition upon its actual condition.

Address:No. 115, Yuanxi Rd., Annan Dist., Tainan City 709 , Taiwan (R.O.C.)

Service Hours:Mon. - Fri. 8:00am-5:00pm

E-mail:zhu.desui@msa.hinet.net

E-mail:zds115@zhudesui.com.tw